How We Make Our Famous Treats

How We Make Our Famous Treats

Fish is an extremely perishable item and requires preservation if it is to be suitable for future use. Several preservation methods are used around the world to ensure the fish will be of a very high quality in the coming months and years. The aim of all these methods is the same, to extend shelf-life. One of these preservation methods is drying, which is the oldest known method of preserving perishable food items including fish. The Vikings introduced the drying of fish into the UK around 1,200 years ago in the 9th Century AD.

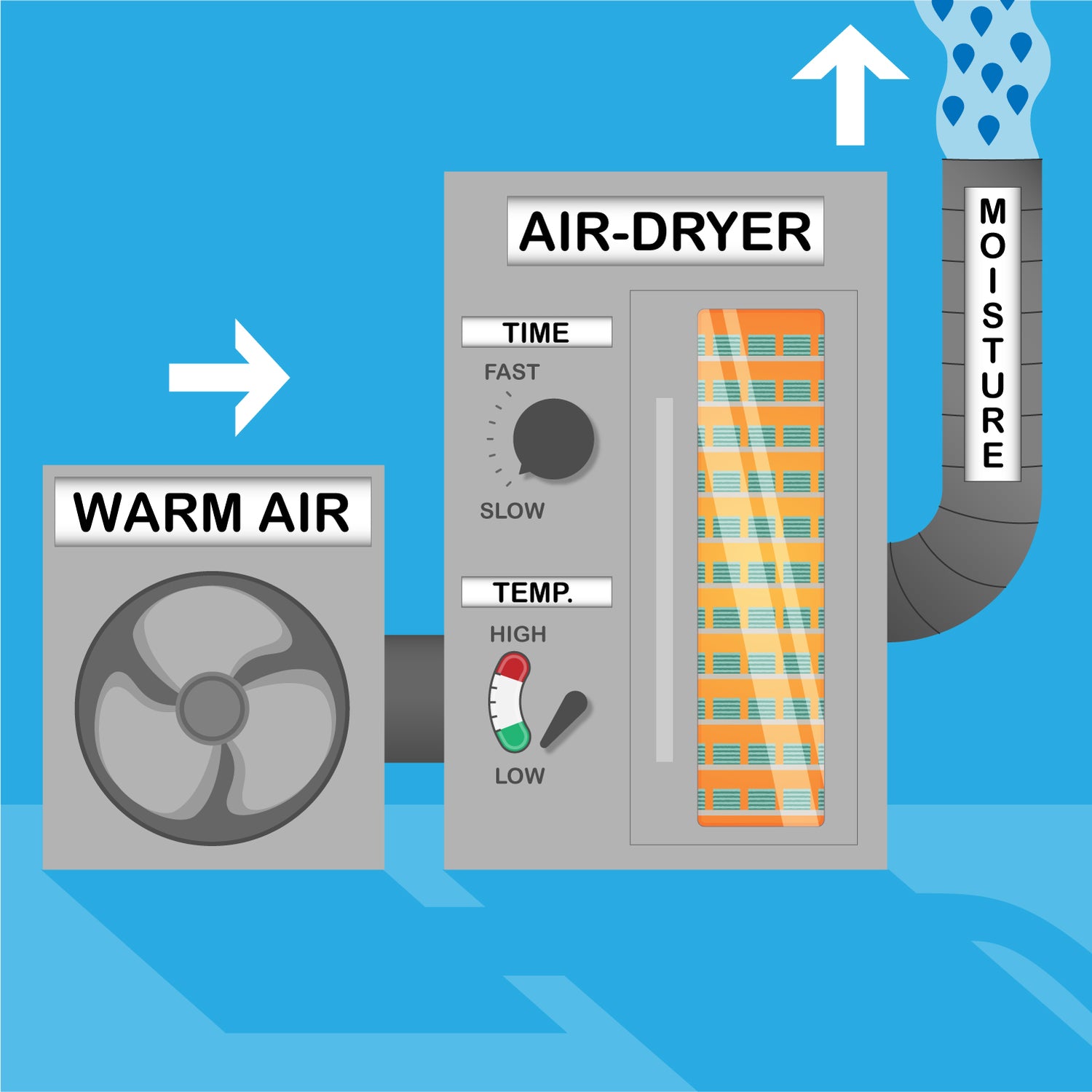

The term “drying” ‘is actually the “dehydration’’ of a food product and involves removal of water content from the fish body. Drying fish can take several days, but by doing so we keep proteins and intrinsic nutritional properties intact. This drying process is practiced under controlled operational parameters like air temperature, relative humidity, air velocity etc. Our practice is to dry fish in an enclosure provided with facilities to control these parameters and guarantee that no outside contamination will be allowed.

Where does our fish come from?

At Skipper’s, we use only high-quality, human-grade fish sourced locally from established and trusted fish merchants in Grimsby or Hull, or from other areas of the UK. Most of our fish is caught from sustainable fisheries and fishing zones around the UK and the EU, with salmon from Scotland or Norway and Cod and Haddock from the cold waters of Iceland and Denmark.

We’re passionate about sustainability and ensure that every product is traceable, from the time it’s caught to its journey through our rigorous quality control processes. All our fish treats are rich in protein and natural Omega-3 oils, crafted to promote your dog’s health while respecting the environment.

Why dry instead of cook?

Drying is a gentle and natural preservation method that retains the nutritional integrity of the ingredients while enhancing their shelf life. Unlike cooking, which often requires high temperatures that can degrade vital nutrients, drying carefully removes moisture without compromising the essential proteins, vitamins, and minerals your pet needs. This process ensures that every bite of our treats is as wholesome and nutrient-rich as the fresh ingredients we start with.

Additionally, drying creates a texture that pets love—crispy, chewy, and satisfying. By avoiding the cooking process, we also steer clear of the need for artificial preservatives or additives. The result? Treats that are not only healthier but also closer to what your pet would naturally enjoy in the wild. Drying is the perfect way to keep our products simple, nutritious, and packed with flavor.

How We Do It

At Skipper’s Pet Products, we believe in keeping things simple and natural. Our drying process starts with carefully selected, high-quality ingredients, sourced responsibly to ensure the best for your pets. Each ingredient is prepared with care, cleaned thoroughly, and then arranged in specialized drying chambers designed to maintain optimal airflow and temperature.

Using low, consistent heat, we gently remove moisture over time. This slow process preserves the natural flavors and nutrients while achieving the ideal texture pets love. Our drying method also ensures that the treats stay safe and shelf-stable without the need for artificial preservatives or chemicals. From start to finish, every step is guided by our commitment to delivering healthy, delicious treats that your pet can enjoy with confidence.

Our Factory

Our factory resides at the heart of the UK's fishing industry in Grimsby. In 2022 we introduced brand new state of the art walkn in air-dryers and in 2025 we installed 2 brand new ovens to help expand our range.

The Process

At Skipper’s, we take pride in crafting wholesome, natural treats through a simple yet meticulous process. From sourcing sustainable, human-grade fish to carefully preparing, drying, and packaging each product, every step is designed to ensure maximum quality and nutrition. With a commitment to traceability and care, we make treats that pets love and owners trust.

Step 1

Preparing the Fish

Sustainably sourced fish is skinned and filleted. The fillets go to places like Supermarkets and fishmongers while we take the skins that would otherwise not be used.

Step 2

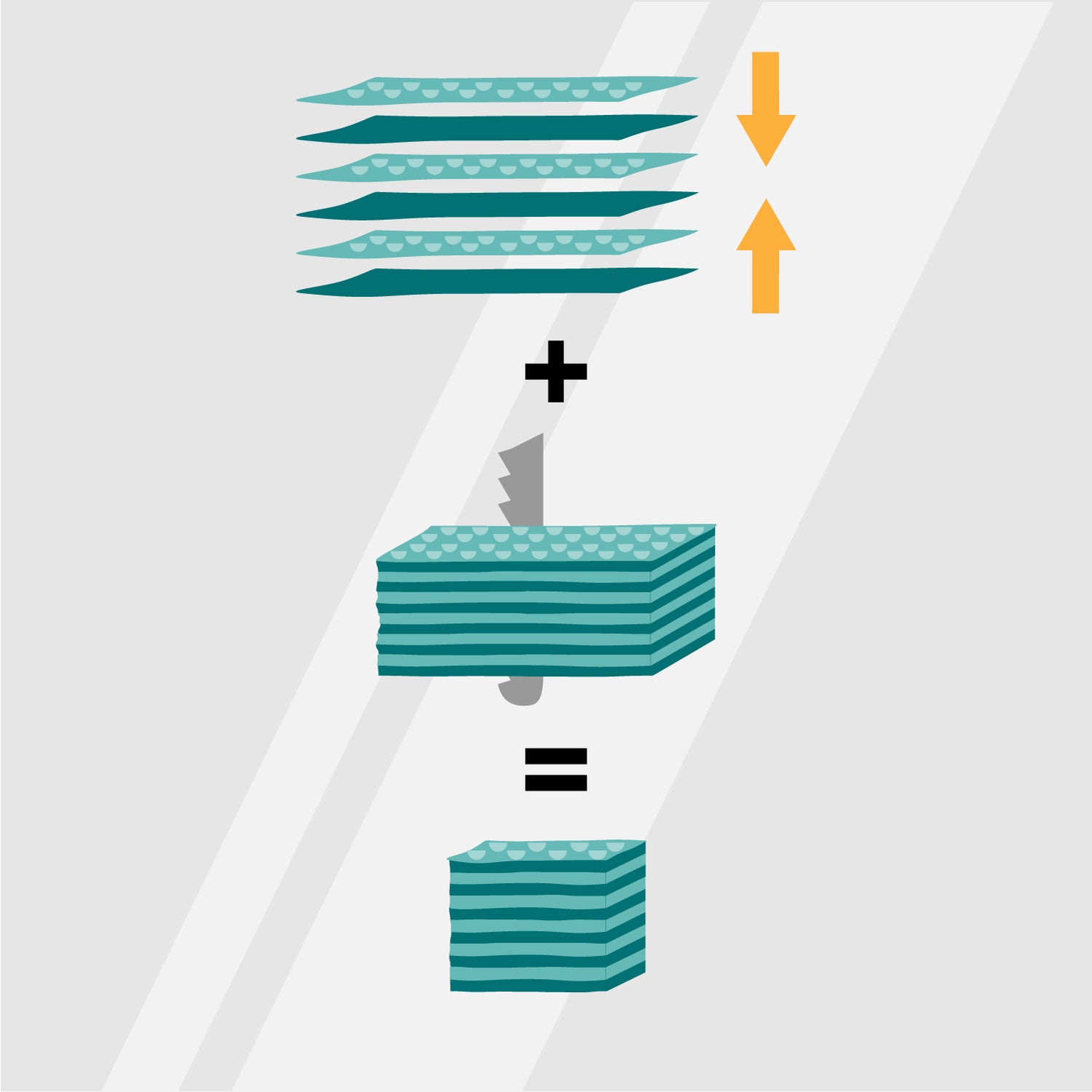

Shaping

With some products like our Flatties and Twists we grade the skins by size and twist and fold them by hand into the required shapes to make the products our customers love.

Products like our Fish Skin Cubes and Fingers are made from lots and lots of layers of fish skins, pressed tightly together into blocks and frozen, before being cut into the required shapes by hand on a bandsaw.

Step 3

Drying

The skins go into our special air-drying ovens, at low temperatures, for 2-5 days, and we gently lift the moisture from the skins.

Step 4

Packing

Once the skins are perfectly dried to lock in all of that fishy goodness, we sort, pack and weigh them into our bags by hand before sending them through a metal detector to ensure the quality is perfect and nothing has gotten in that shouldn't have during the production process. They're then ready to send to our customers' lucky dogs!

Check out the process in our animated video

The Result

The result of our careful process is a range of treats that are as nutritious as they are delicious. Each bite is packed with high-quality protein, natural Omega-3 oils, and essential nutrients to support your pet’s health and vitality. Our treats are not only irresistible to pets but also give owners peace of mind, knowing they’re giving their furry friends a product made with care, sustainability, and expertise.

At Skipper’s, we’re proud to deliver treats that go beyond expectations—because your pets deserve nothing less.

That's why we've become the biggest UK producer of air-dried fish treats for dogs and why we're trusted by thousands of customers and enjoyed by dogs up and down the country.

Our Most Popular Air-Dried Treats

-

Fish Skin Cubes

Regular price From £1.99Sale price From £1.99 Regular priceUnit price / per -

Sale

SaleFish Skin Twists

Regular price From £2.50Sale price From £2.50 Regular priceUnit price / per£17.50Sale -

Sale

SaleFish Skin Flatties

Regular price From £2.50Sale price From £2.50 Regular priceUnit price / per£17.50Sale -

Fish Finger Skins

Regular price From £1.99Sale price From £1.99 Regular priceUnit price / per